Continued focus on sustainability

Prevex is one of the few companies worldwide specialising in water traps for kitchens and bathrooms. Prevex has in-depth product development know-how and focuses on flexible water traps that are easy to install and clean.

The company is able to operate in such a narrow niche segment because the KWH Group looks at all its subsidiaries as a whole, and the overall risk diversification in the Group is therefore at an acceptable level.

Environmental initiatives continuing

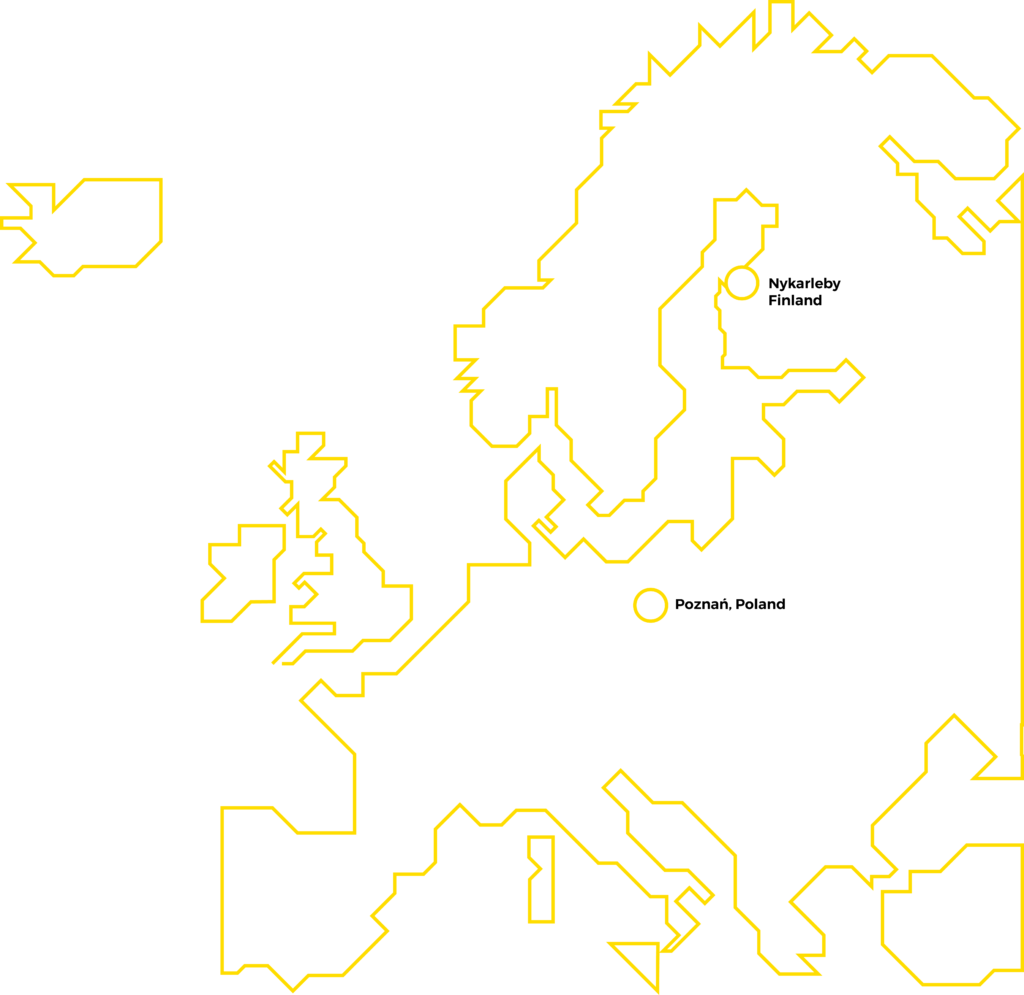

In 2020, Prevex continued the ambitious environmental work that had been started in previous years. This work resulted in several specific measures, primarily concerning the buildings in Nykarleby.

A heat pump now utilises the waste heat from production, saving 800 MWh of energy a year. This is equivalent to district heating for 60 homes and supplies virtually all the heating required for the factory. In addition, solar panels were installed on the production building in summer 2020. When the weather conditions are right, they supply all the power the office needs.

However, the biggest environmental initiative in 2020 involved the factory in Poland switching to 100% renewable power. The factory in Nykarleby made the same switch a year earlier. This means that all Prevex water traps are made only with renewable electricity.

At the same time, the product development work continued to try and find more sustainable materials for the water traps themselves, and Prevex hopes to be able to present the results of this work in 2021.

Brand renewal and reorganisation of production

In 2020, Prevex began a major brand renewal process which will be completed in 2021. The work began with a thorough analysis of customer needs, which resulted in the insight that Prevex needs to focus more on long-term partnerships. This is because Prevex’ know-how is best employed in the type of customer relationships that permit deep collaboration on product development.

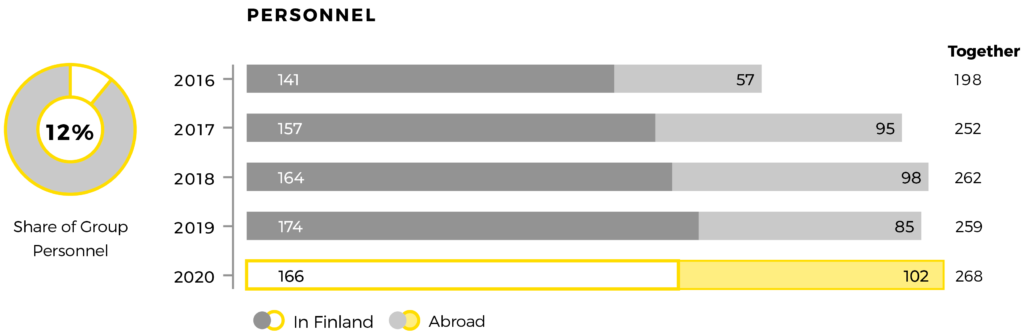

Prevex also reorganised production in 2020. The company’s production, injection moulding and demanding automation are now concentrated in Nykarleby in Finland, while the Polish unit handles more extensive assembly work. This leads to better overall logistics and efficiency.

Initiatives during the pandemic

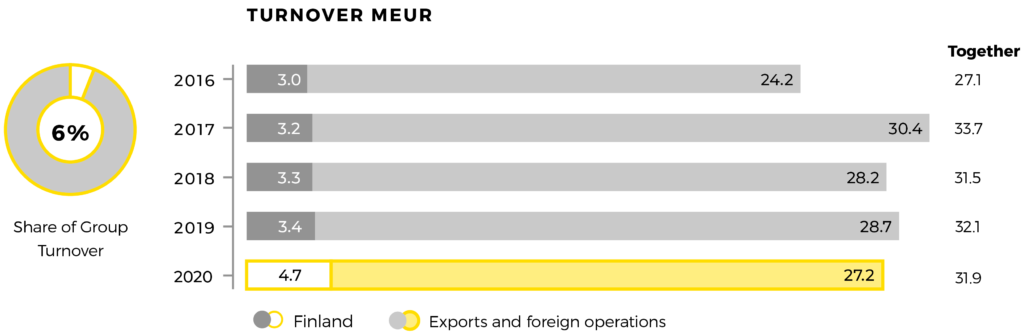

Like so many other companies, Prevex was initially hit hard when the Covid-19 pandemic began in March 2020. Nevertheless, the upturn in early summer was just as fast as the downturn in the spring, resulting in sales for the full year being roughly the same as in 2019.

While part of production was idle in April-May, Prevex was also able to do its bit to combat the epidemic. At short notice, the company began making earpieces for visors for the healthcare sector. As there was a great shortage of personal protective equipment in the healthcare sector at the time, staff found this initiative very meaningful.

Management